- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Products

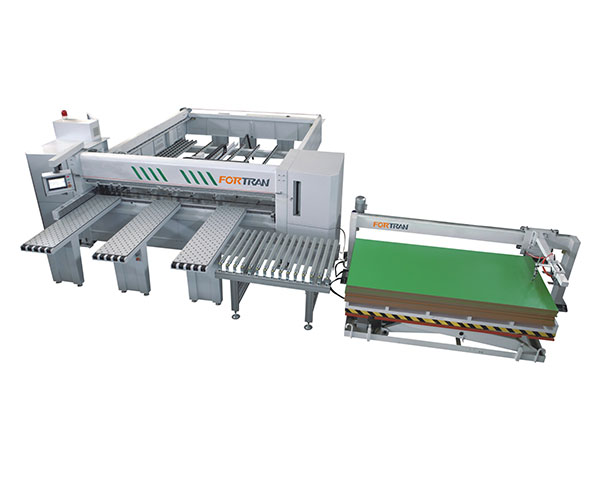

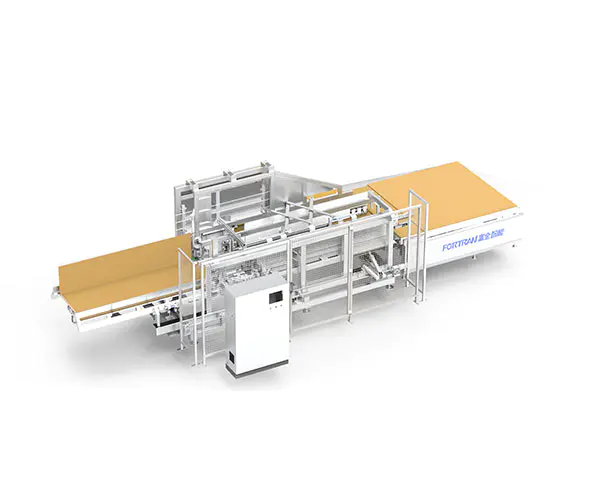

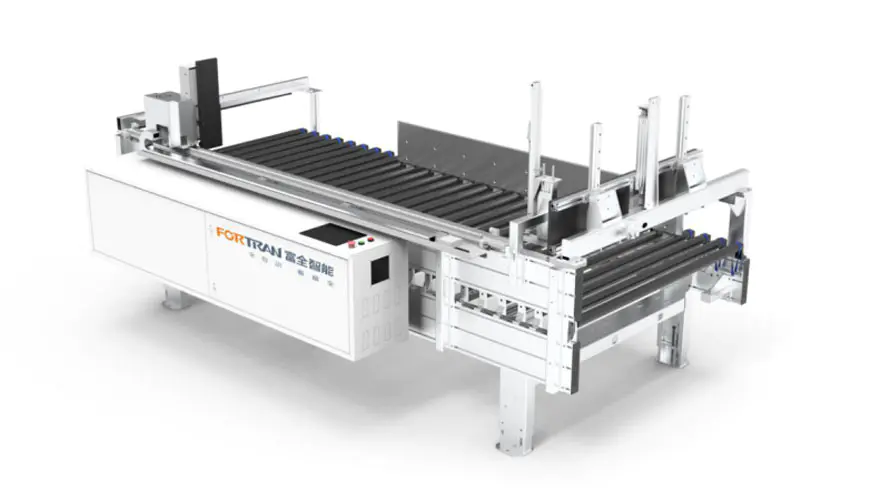

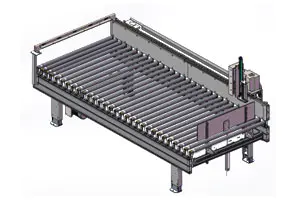

Integrated Intelligent Measuring Station

The integrated intelligent measuring station is mainly used to measure the stacking length, width, and thickness of each package of boards before packaging.

Send Inquiry

Product Description

Overall Machine Image

Equipment Parameters

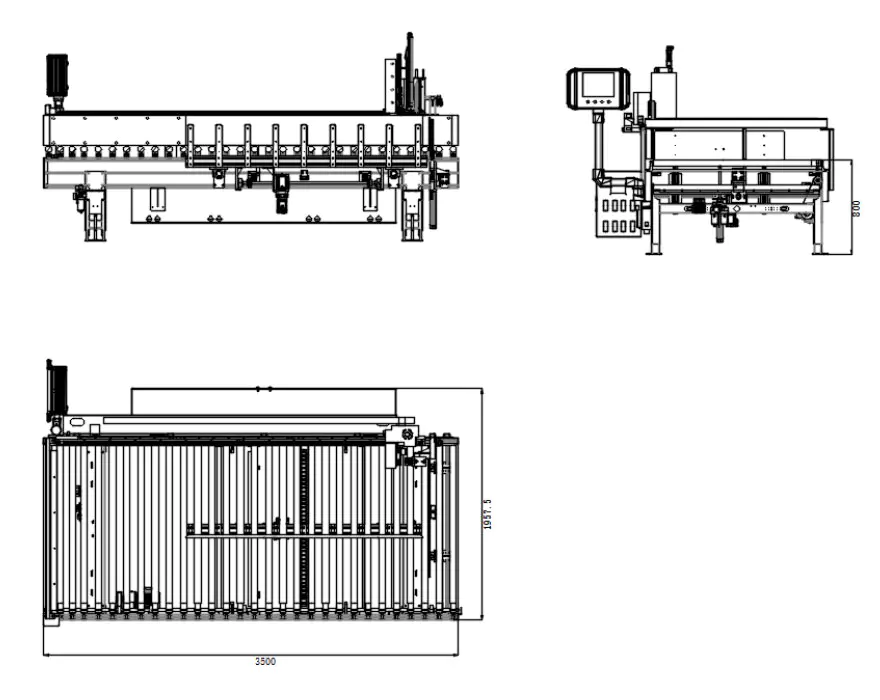

| Overall DimensionsL*W*H(mm) | Equipment Weigh (kg) | Measuring Load Capacity(kg/㎡) | Total Power(kW) | Measuring Accuracy(mm) | Workbench Height(mm) |

| 3500*1960*1800 | 800 | 50 | 2.25 | ±0.5 | 800±50 |

Measuring Parameters

| Board Length Processing Range L(mm) | Board Width Processing Range W(mm) | Board Thickness Processing Range H(mm) | Measuring Efficiency (times/min) | Conveying Speed(m/min) |

| 350-2800 | 200-1200 | 18-250 | 4-6 | 0-35 (frequency conversion adjustable) |

Product Features

1.The feet are cut and drilled by laser, ensuring precise hole positions. They are bent by a CNC bending machine for accurate angles.

2.The feet are made of cold-rolled pickled steel plates with flat surfaces. After shot blasting and sandblasting, they are spray-coated for strong corrosion resistance.

3.The feet adopt movable adjustable foot cups, offering strong adaptability to ground flatness.

4.The hot-dip galvanized rollers are covered with Italian imported hoses, effectively preventing surface scratches of workpieces due to friction and ensuring intact workpiece surfaces.

5.The elastic belt drive produces low noise during operation. The elastic belt has high toughness and a long service life.

6.Both the stoppers and backing plates are made of compact laminate, and the supporting plates are made of smooth PE plates, resulting in low friction resistance.

7.The integrated length and width measurement design reduces the floor space.

8.Automatic control enables measurement with high accuracy, high efficiency, and low failure rate.

9.The guide rail of the mechanical positioning device adopts Hiwin guide rail, featuring high precision, low vibration, and long service life. The transmission uses gear and rack for fast speed and high precision. The positioning adopts a servo motor, ensuring precision, efficiency, speed, high torque, and small size.

Function Overview

The integrated intelligent measuring station is mainly used to measure the stacking length, width, and thickness of each package of boards before packaging. It measures length first, then width, and finally height, with fast speed, small floor space, and high efficiency. It adopts a wide and thick aluminum profile frame, which is elegant and has excellent stability.

| Serial number | Name | Feature | Module |

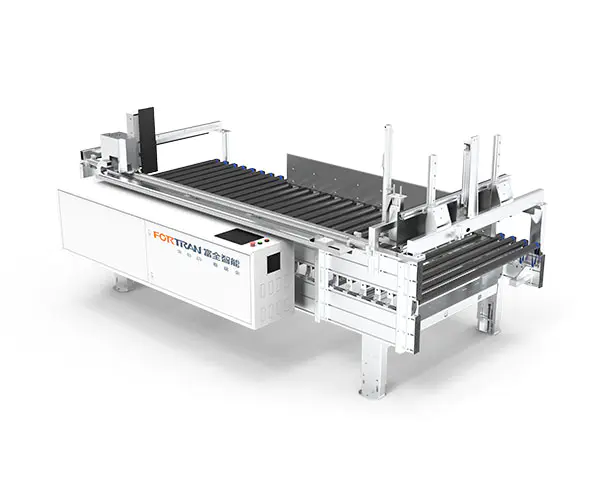

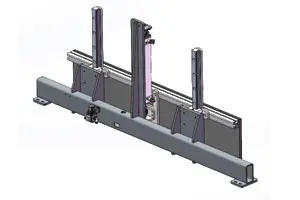

| 1 | Length-Measuring Movable Beam Assembly | A high-precision servo motor transmits power through a planetary reducer, providing high torque, low noise, and stable power. Power is transmitted through a synchronous shaft and gears to realize rapid movement of the entire mechanism, thereby improving efficiency. |

|

| 2 | Length-Measuring Fixed Plate Assembly | This end serves as the measurement reference plate. The baffle is powered by an air cylinder for vertical lifting and achieves fast and stable linear movement with the help of Hiwin precision guide rails. |

|

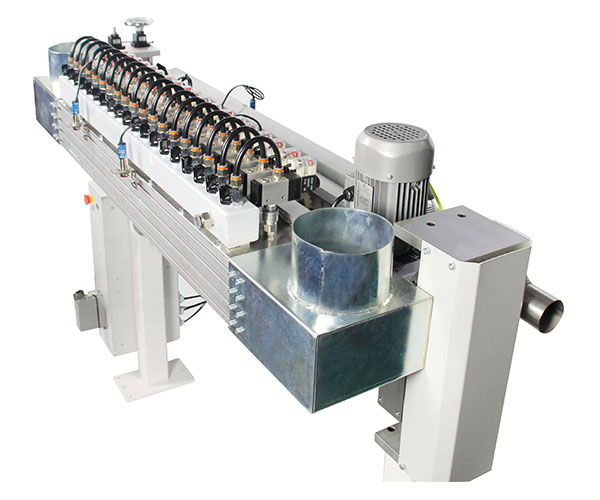

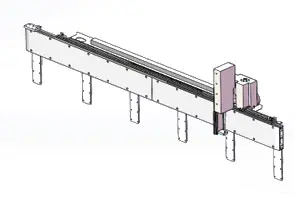

| 3 | Measuring Roller Conveyor Frame | The rollers adopt Italian imported rubber-covered rollers with smooth and bright surfaces and high friction, ensuring absolutely stable conveying of packages and greatly reducing the possibility of sliding friction. They are subjected to shot blasting and spray coating to ensure the overall appearance and frame rigidity. |

|

| 4 | Roller Motor Assembly | Uses imported geared motors for durability. Power is stably transmitted to the rollers through synchronous pulleys and synchronous belts. |

|

| 5 | Width-Measuring Section Measurement Power Mechanism | The horizontal power system adopts a high-precision servo motor combined with a precision reducer to ensure the stability of the transmission system. |

|

Three-View Drawings

Hot Tags: Integrated Intelligent Measuring Station

Related Category

Unpowered Roller Conveyor Series

Scissor Type Hydraulic Lifting Table Series

Intelligent Factory Furniture Production Line Series

Intelligent Packaging Line Series

Powered Belt Conveyor Series

Intelligent Factory Furniture Production Line Series Single Machine

Roller Series

Door Solution

Send Inquiry

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.