- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

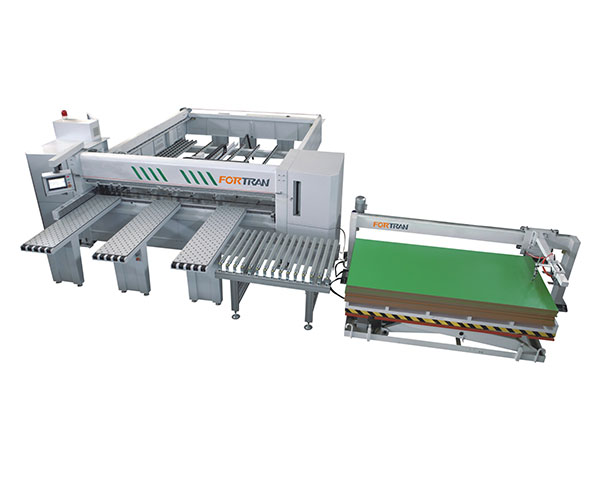

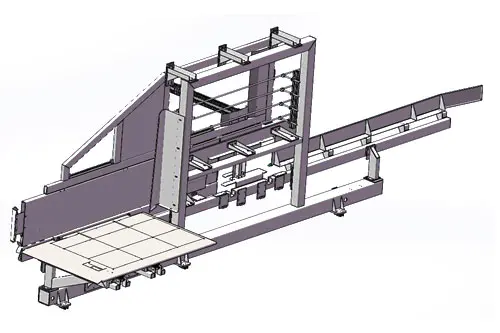

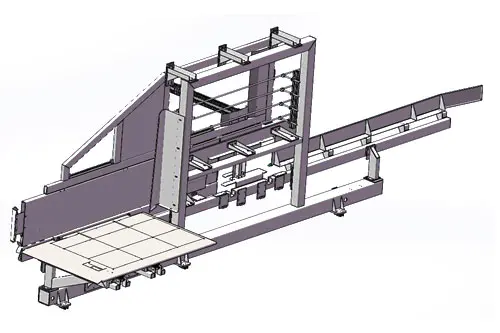

Automatic Box Folding Machine

This Automatic Box Folding Machine is used in cartons into boxes; We look forward to cooperating with you, if you want to know more, you can consult us now, we will reply to you in time!

Send Inquiry

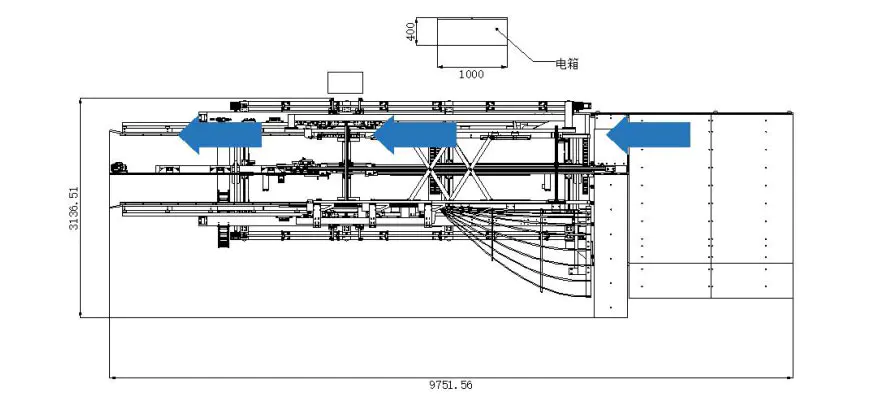

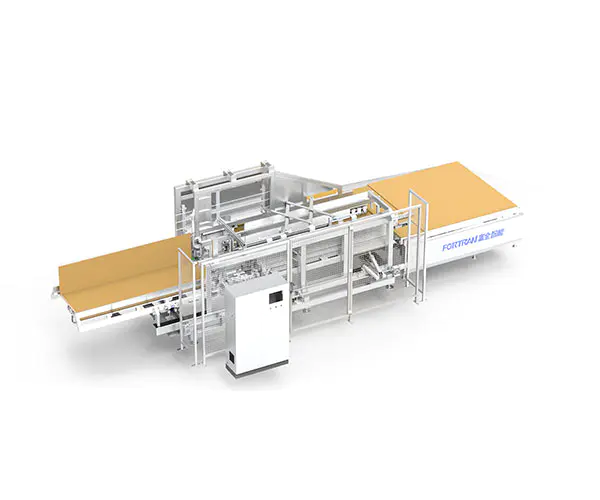

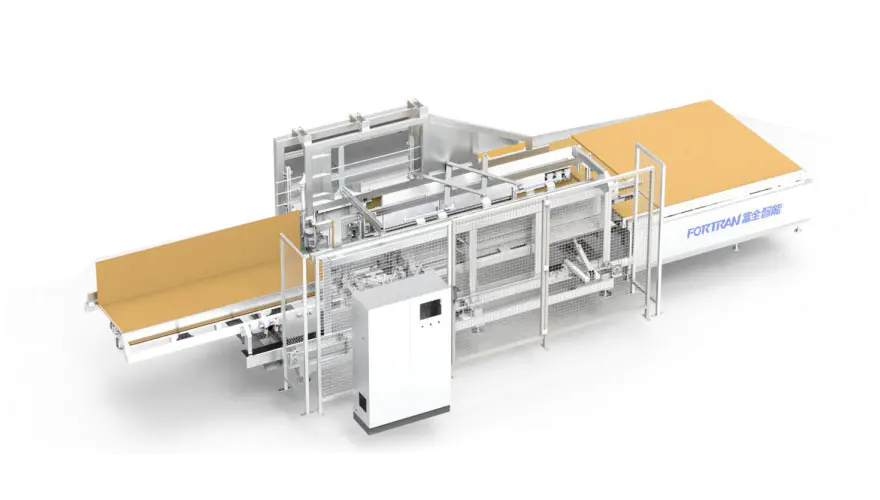

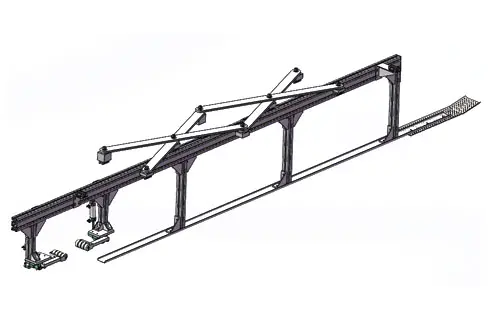

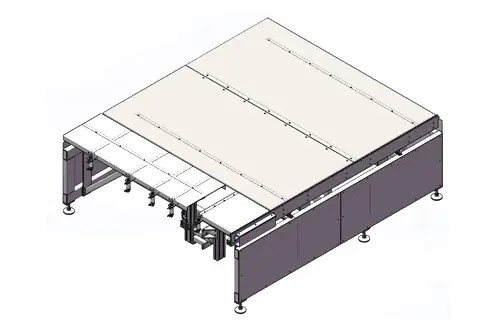

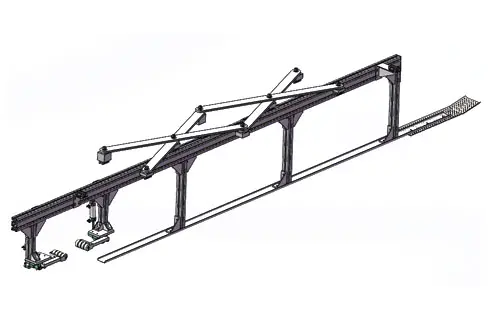

Overall Machine Image

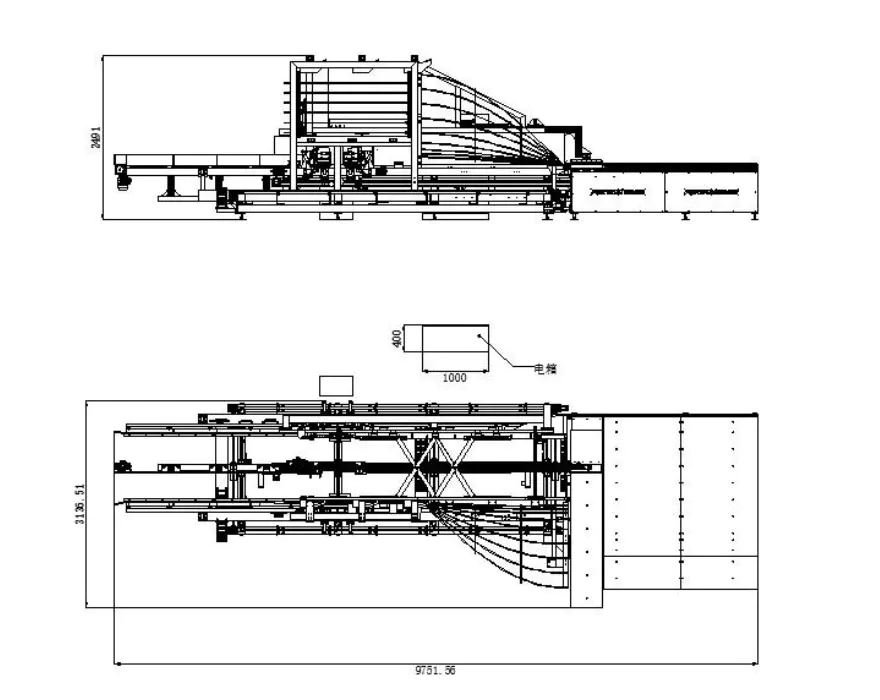

Equipment Parameters

|

External dimensions L*W*H(mm) |

Self-weight of equipment(kg) | Power supply(kW) | Conveying load(kg) | Working height(mm) |

| 9760*3550*2500 | About 3700 |

4.5kW (excluding gluing unit) |

50 | 830±40 (undetermined. Depends on customer |

Processing scope

| Carton processing range L(mm) | Carton processing range W(mm) | Carton processing range H(mm) | Folding efficiency(times/min) | Corrugated paper thickness(mm) |

| 400-2800 | 320-900 | 40-250 | 5-7 | 2.5-6 |

1 Core accessories brand:servo motor--Inovance ;synchronous belt--Gardner;seat bearing--TR;frequency conversion motor---Inovance:

2 The overall rack pipe is welded and processed by gantry, which is highly accurate, reliable anddurable.

3 The linear mechanism of the folding box machine is guided by precision linear guide rail, which is highly reliable and durable.

4 The suction cup transmission paper adopts a high-precision servo motor, which is easy to control and can improve the accuracy of the equipment;

5 The machine can be used alone or in combination with the customized packaging line. The way of use is changeable and flexible

1 Uses

A. This Automatic Box Folding Machine is used in cartons into boxes;

B. This equipment is used to make boxes of M/A-0410 model cartons;

C. First, benchmark the carton, press the corresponding input size and start, and enter the equipment to automatically make a box;

2 Overview of the working principle

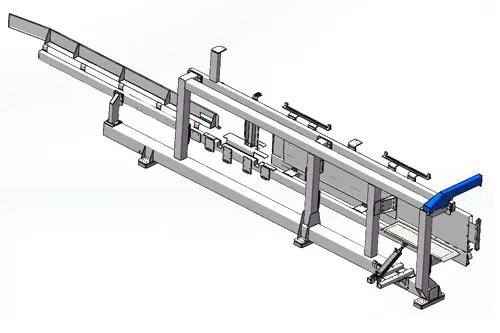

The whole set of equipment is divided into five parts: feeding platform mechanism, main frame mechanism, fixed side folding mechanism, mobile side folding mechanism, and median transmission mechanism:

A. When working, the operation screen input corresponds to the size of the folding box; after the positioning is ready, after the paper skin is aligned with the front benchmark and the side benchmark in the positive direction, press the green start button device to automatically start the suction cup to absorb the paper skin into the entrance of the folding box machine section;

B. The suction cup drives the paper skin into the folding part, and the fixed edge and the moving long edge correspond to the folding edge enter, and then automatically spray glue at the specified glue spray position, and the front end folding position is completed one by one;

C. After the front-end folding box reaches the designated position, after the downward pressure of the cylinder is tightened, the suction cup immediately drops and resets back to the origin, and the back suction cup is attached to the back end of the paper and waits for it; after the fixed side and the moving side folding edge work at the same time, the flip group is reset after completion; The back-end suction cup drives the paper skin forward to the moulding position of the back-end folding box, and automatically spray glue to the designated position;

3 Functional Structure"

-

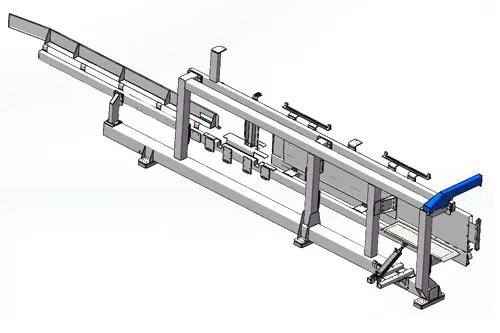

Feeding table structure

-

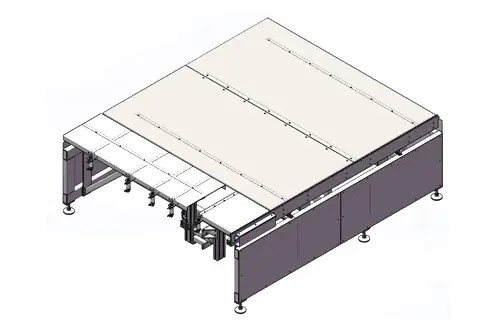

Rack base structure

-

Fixed side folding rack set

-

Mobile side folding rack set

-

Five parts of the median drive mechanism

-

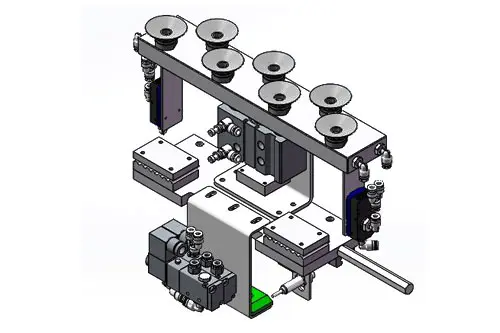

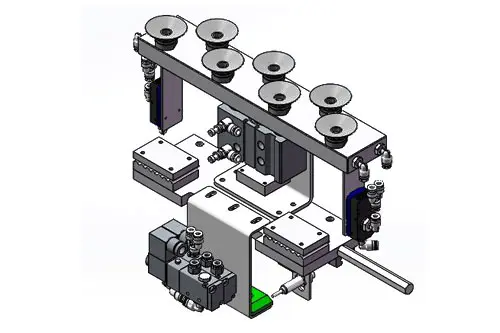

Mid-level suction cup group

-

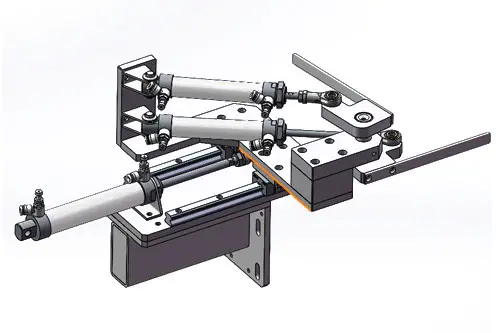

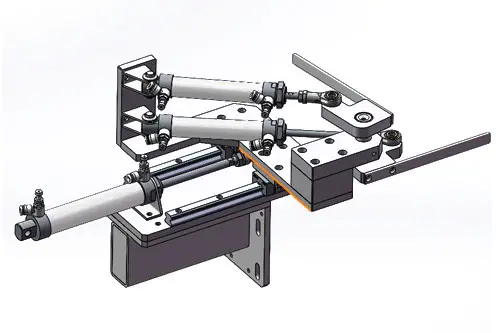

Folding expansion group

-

Press plate group

-

Side-turning group

-

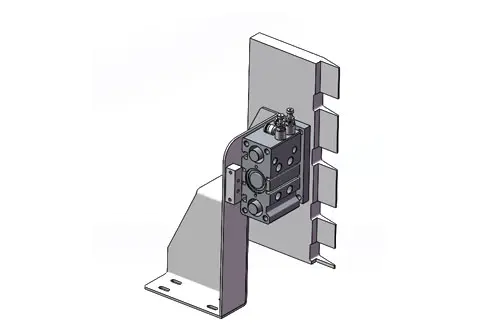

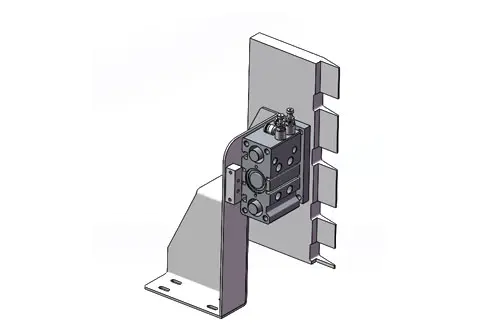

Swing arm ear seat group

-

Mid-level auxiliary edge pressing group

-

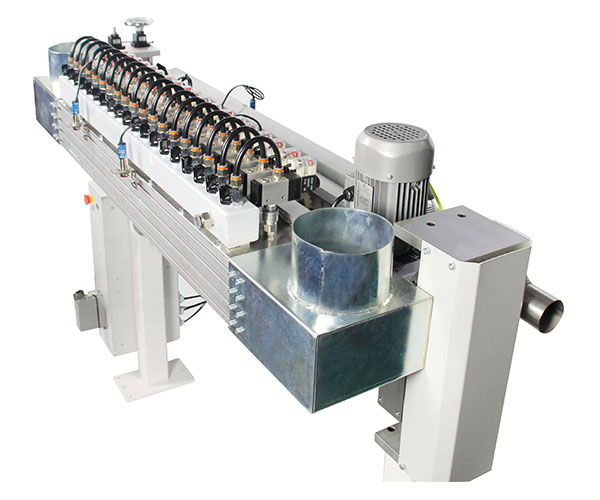

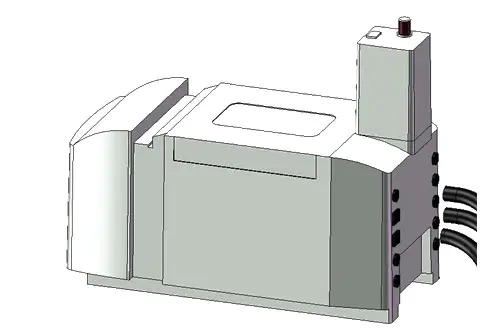

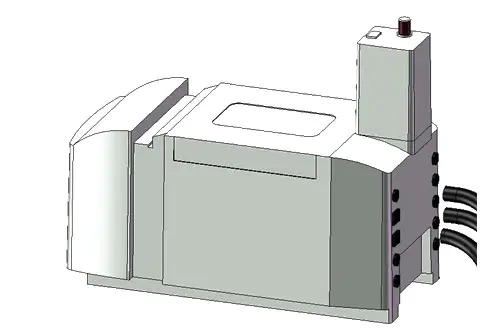

Glue machine system

| Serial number | Name | Distinguishing feature | Model |

| 1 | Feeding table structure | The front material table is positioned at the flat board position, and the cylinder controls the lifting and positioning pin;the side servo motor accurately locates the preparation position of the paper skin feed; |

|

| 2 | Rack base structure | The base of the mainframe rack, the servo linkage control servo motor drive mobile folding mechanism and the median drive mechanism are more accurate; |

|

| 3 | Fixed side folding rack set | Fixed side folding frame, short edge cylinder folding, sheet metal auxiliary guide feed on both sides;rack welding gantry machining;high assembly accuracy, high operation accuracy, ensuring long service life and good stability of the equipment; |

|

| 4 | Mobile side folding rack set | Moving side folding frame, long-side cylinder folding, sheet metal auxiliary guide feeding on both sides;rack welding gantry machining;high assembly accuracy, high operation accuracy, ensuring long service life and good stability of the equipment; |

|

| 5 | Five parts of the median drive mechanism | The servo control drive, the middle suction cup group drives the paper skin movement, the discharge motor drives the chain to drive the paper skin discharge; |

|

| 6 | Mid-level suction cup group | The belt of the servo motor drives the movement, the cylinder rises and lowers, and the suction cup vacuum absorbs the paper skin transmission, accurate operation and positioning; |

|

| 7 | Folding expansion group | The front and rear cylinder expansion cooperates with the guide rail to move back and forth, and the grouping cylinder swing arm mechanism realises the folding of different specifications and sizes; |

|

| 8 | Press plate group | The cylinder expands before and after, and acts on the bending of the ear to straighten the box into a right angle; |

|

| 9 | Side-turning group | It is mainly responsible for pressing the front and rear ends of the carton upwards, and the cylinder telescopic transmission drives the swing arm, so that the hot melt adhesive is firmly and stable; |

|

| 10 | Swing arm ear seat group | The cylinder drive expansion drives the swing arm. After the swing arm is positioned at a right angle, the lower pressure cylinder clamps the paper skin, with the side-turning group compression hot melt adhesive paste to make it firm and stable; |

|

| 11 | Mid-level auxiliary edge pressing group | The long swing arm cooperates with the guide rail to achieve a fully automatic middle position in the middle of the carton;the front block material assists the lower suction cup group to absorb the paper skin;the back end is divided into two groups of front and rear cylinders to control the front and back of the swing arm to assist the paper edge of the paper;to prevent the paper skin from being too wide and causing the problem of inaccurate moulding. |

|

| 12 | Glue machine system | In the glue machine system, we use a complete set of pure imported accessories of Le Baide, which can realise continuous glue spraying, complete functions, simple setting and convenient operation; |

|

Three views (Undetermined because size changes according to parameters)

Schematic diagram of production process mode (Undetermined because size changes according to parameters)