- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Products

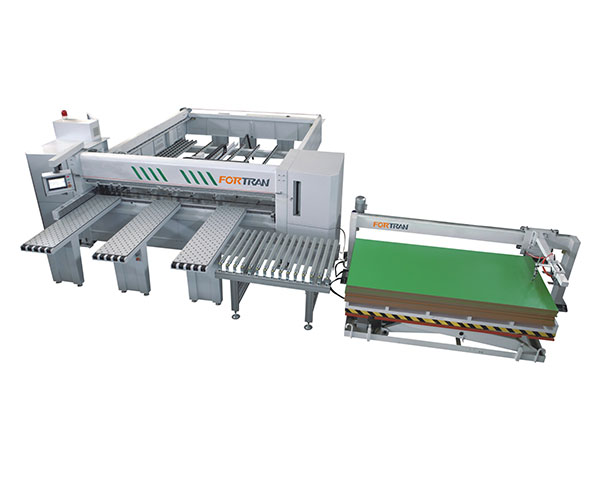

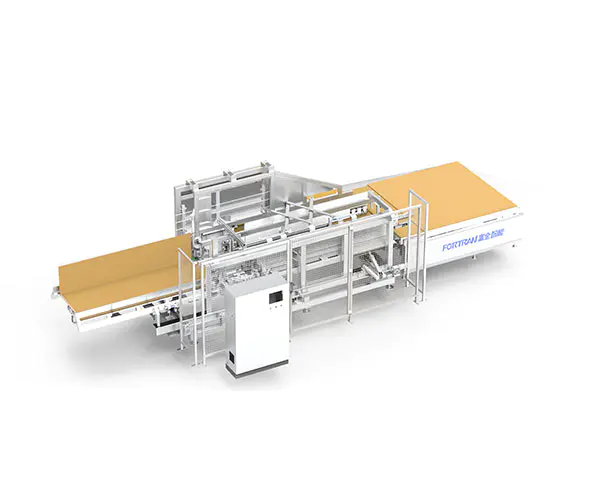

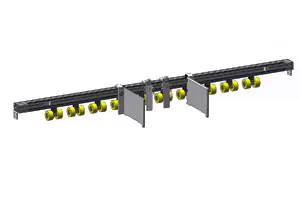

Fully Automatic Paper Cutting Machine

The Fully Automatic Paper Cutting Machine is used for continuous fixed-length processing of corrugated paper and single sheets to produce folding cartons. We look forward to cooperating with you, if you want to know more, you can consult us now, we will reply to you in time!

Send Inquiry

Product Description

Machine specifications

|

Dimensions L*W*H(mm) |

Basic Specifications |

Power supply (kW) |

Cutting Speed (M/min) |

Working height (mm) |

| 6700*3650*3000 | 7 vertical+1 horizontal knives, with single-sheet feeding and continuous-sheet feeding modes | 5.25 | 0-120 | 850 |

Processing Parameters

| Min. Cutting Length L (mm) | Max. Cutting Width W (mm) | Cutting Thickness for Corrugated Paper H (mm) | Longitudinal Blade Spacing Precision (mm) | Efficiency (PCS/min) |

| 300 | 2500 | 2.5-6.5 | ±1.5 | 0-12 |

General Description of Functions

The Fully Automatic Paper Cutting Machine is used for continuous fixed-length processing of corrugated paper and single sheets to produce folding cartons.The machine performs creasing in both the transverse and longitudinal directions,intermittent cutting,and cutting processing on the corrugated paper.Fixed-length cutting allows for both mass production and customized production.The machine can be used as a standalone unit or as the initial part of a packaging line.

| No. | Item | Features | Model |

| 1 | Paper Storage Rack | The paper storage rack is made of pickling plate through bending processing, featuring a simple structure, reliable construction. It is painted to ensure an attractive appearance and excellent rust resistance. The standard configuration includes a continuous cardboard material rack and a single-layer cardboard feeding flow strip. |

|

| 2 | Frame Structure | The frame is manufactured by precision machining after welding rectangular steel tubes and steel plates. It ensures high assembly accuracy and operational precision, guaranteeing a long service life and excellent stability of the equipment. |

|

| 3 | Drive Mechanism | The feeding pressure wheel is made of PU material, with a bright and beautiful surface and friction, which can effectively improve the reliability of paperboard conveying. Meanwhile, the traction drum is imported from Germany, durable and long-lasting;it can be manually adjusted and fixed to the side. |

|

| 4 | Cross-Cutting Structure | The power is provided by a high-precision servo motor combined with a reducer and a synchronous wheel mechanism, which achieves high-speed and precise positioning, thereby ensuring the accuracy of the carton cut; |

|

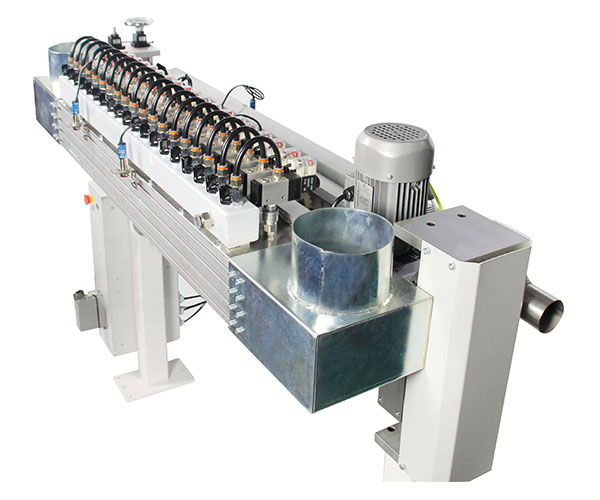

| 5 | Longitudinal Cutting Unit | This mechanism is mainly composed of seven sets of knife holders.The transverse knife belt servo drives the positioning of the longitudinal knife, which can meet the requirements of efficient operation while also ensuring durability. |

|

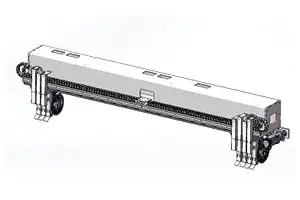

| 6 | Adjustable Storage device | The rollers are controlled by a servo motor plus a speed reducer. To improve operational accuracy and efficiency, we use a high-precision bevel gear speed reducer equipped with a high-precision servo motor. A vacuum suction structure is adopted to adsorb cardboard, enabling better conveyance of single-layer cardboard. |

|

| 7 | Machine Enclosure | The primary focus is on decorating the machine itself.An exterior protective cover is added to the machine, which is treated with powder coating to ensure an aesthetically pleasing and durable finish that does not chip or peel. The observation window at the front of the machine is made of a deep blue acrylic panel, which is not only visually attractive and elegant but also highly resilient and resistant to shattering.Additionally, an aluminum alloy slide rail is installed, which has a glossy surface and operates silently without any noise. |

|

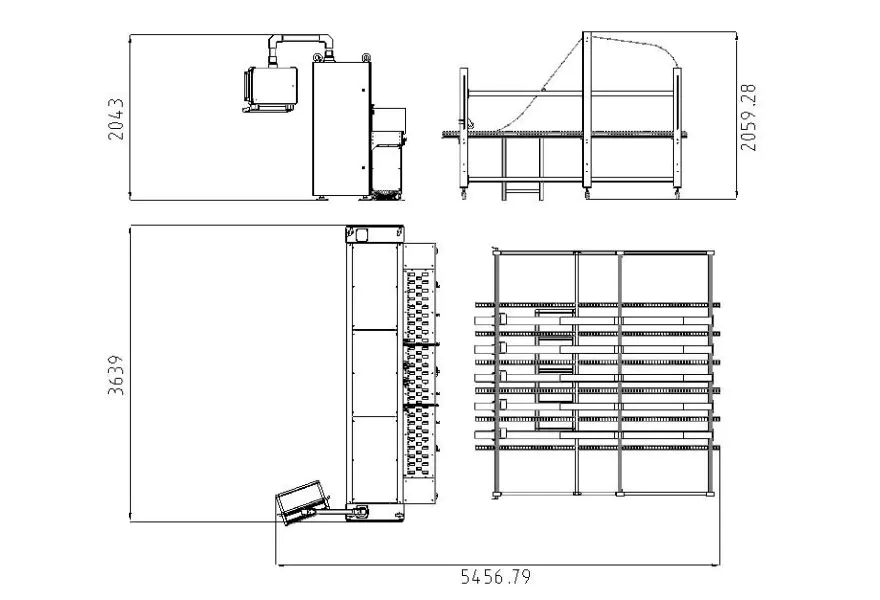

Three-View Drawings

Consumable Requirements

A.Continuous corrugated paper width:400–2350 mm;

B.Stacking height,including a 120 mm pallet:Maximum 1300 mm;

C.Stacking width,maximum:1300 mm;Length of corrugated paper at the discharge point:Minimum 300mm;

D.Longitudinal tolerance for fixed-length cutting:Maximum 0.5%;Transverse tolerance for fixed-length cutting:Maximum±2.0 mm;

E.Corrugated paper thickness:2.5–6 mm,±0.2 mm;Maximum raw material quality up to 2.30 BC(according to DIN 55468 standard);

F.The quality of the cardboard complies with the DIN 55468 standard;

G.Single corrugated,maximum thickness of approximately 4 mm(quality:1.10–1.40);Double corrugated,maximum thickness of approximately 6 mm.

2. Carton types

| Serial number | Name | Image | Paper feed direction | Minimum size |

| 1 | Ordinary box |

|

longitudinal |

Length: minimum 400mm Width: minimum 36mm Height: minimum 225mm |

| 2 | Ordinary box |

|

longitudinal |

Length: minimum 400mm Width: minimum 36mm Height: minimum 225mm |

| 3 | Heavenand Earth Cover |

|

longitudinal |

Length: minimum 400mm Width: minimum 225mm Height: minimum 18mm |

| 4 | Middle Seal Box |

|

longitudinal |

Length: minimum 400mm Width: minimum 450mm Height: minimum 18mm |

| 5 | Middle Seal Box |

|

longitudinal |

Length: minimum 400mm Height: minimum 450mm Height: minimum 18mm |

| 6 | All-wing box |

|

longitudinal |

Length: minimum 400mm Height: minimum 225mm Height: minimum 18mm |

| 7 | Middle Seal Box |

|

longitudinal |

Length: minimum 400mm Height: minimum 450mm Height: minimum 18mm |

| 8 | Square cardboard |

|

longitudinal |

Length: minimum 400mm Height: minimum 18mm |

Hot Tags: Fully Automatic Paper Cutting Machine, China, Customized, Easy-maintainable, Quality, Manufacturers, Suppliers, CE, 12 months warranty, Quotation

Related Category

Unpowered Roller Conveyor Series

Scissor Type Hydraulic Lifting Table Series

Intelligent Factory Furniture Production Line Series

Intelligent Packaging Line Series

Powered Belt Conveyor Series

Intelligent Factory Furniture Production Line Series Single Machine

Roller Series

Door Solution

Send Inquiry

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.