- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

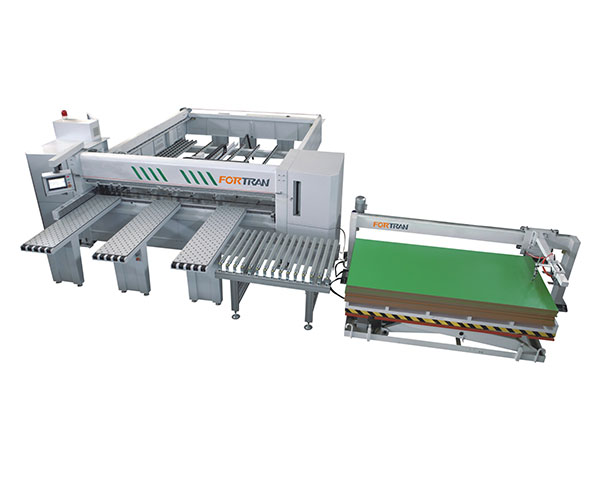

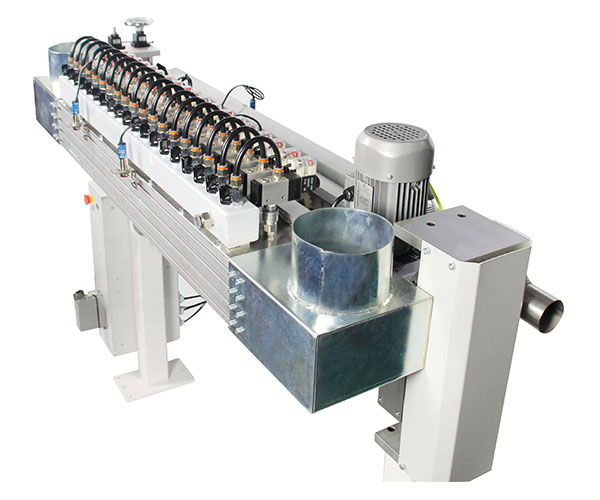

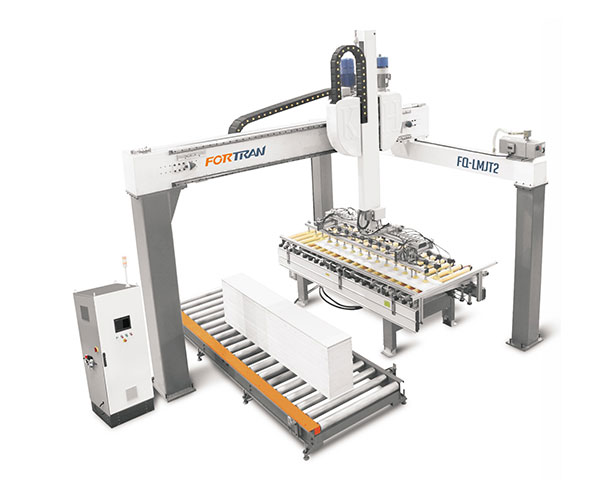

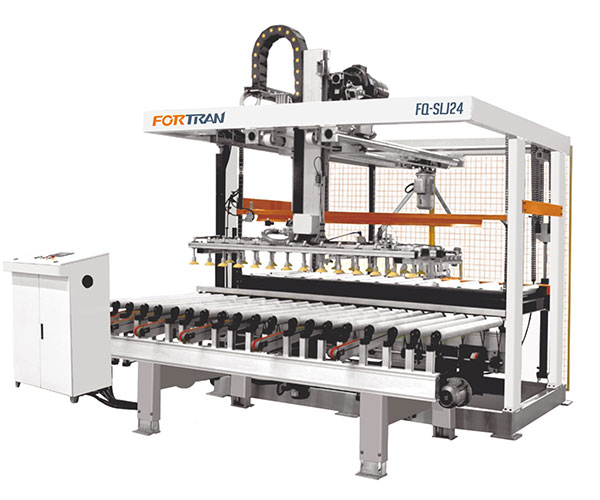

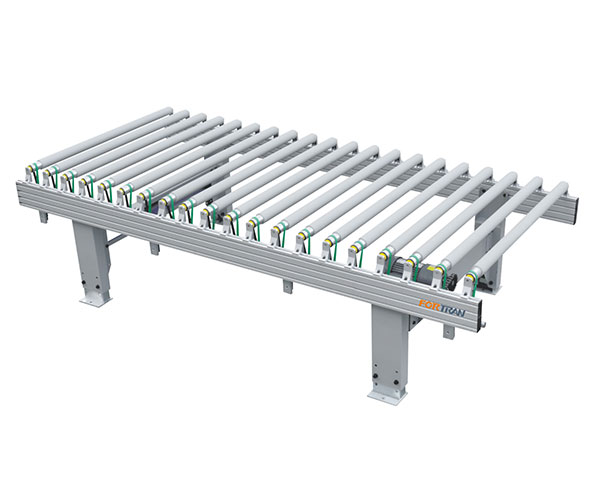

Belt Turnover Machine

The belt turnover machine is an industrial automation device primarily designed for 180° flipping of materials during conveyance. It is widely used in sectors like building materials, furniture manufacturing, logistics, and plate processing.

Send Inquiry

Core Functions

By the coordinated operation of its belt conveyor system and mechanical turnover mechanism, the machine can accurately flip materials such as plates, coils, and boxed goods. This meets the needs of material turning, quality inspection, and pre-processing preparation in production workflows. It replaces traditional manual flipping, significantly boosting efficiency and cutting labor costs.

Equipment Features

High Automation Level: Equipped with a visual control interface, it allows one-click setup of turnover processes and supports continuous, large-scale operations.

Strong Compatibility: It can adapt to conveyors of different widths and thicknesses, with turnover parameters flexibly adjustable based on material specifications.

Safety and Reliability: It comes with functions like fault self-diagnosis, overload protection, and emergency stop devices to ensure the safety of equipment operation and personnel.

Stable Structure: Its mechanical design emphasizes rigidity and wear resistance, enabling long-term stable operation in industrial environments with high durability.

Application Scenarios

In furniture plate production, for instance, plates need to be flipped to inspect surface quality before painting or printing. The belt turnover machine can complete the flipping quickly and work with subsequent production lines to achieve automated quality inspection. In logistics, it also efficiently handles tasks like adjusting the label orientation of boxed goods and flipping/arranging internal materials.

Technical Specifications

| Workpiece length | 250-2750mm |

| Workpiece width | 250-1220mm |

| Workpiece thickness | 10-60mm |

| Max workpiece weight | 100kg |

| Reverse Speed | 3-4 times |

| Working air pressure | 0.4-0.6Mpa |