- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

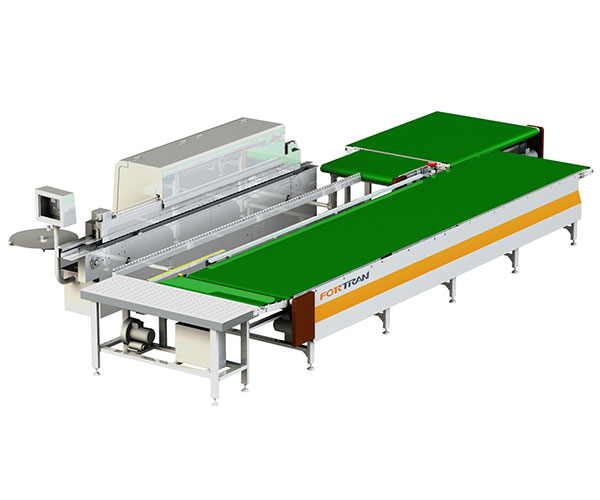

What Is the Role of a Powered Belt Conveyor Series in Modern Material Handling

2025-11-10

Of all the questions we get at Fortran, one stands out in modern facilities What is the true role of a Powered Belt Conveyor Series in today's material handling landscape Having witnessed the evolution of conveyor technology for over two decades at Fortran, I can say its role has transformed from a simple mover to the very backbone of operational throughput and reliability This article dives deep into that critical question

What Core Functions Does a Modern Powered Belt Conveyor Series Perform

A modern Powered Belt Conveyor Series is no longer a passive piece of equipment It is an active, integral component of your production line Its primary role is to ensure a consistent, controlled, and predictable flow of materials From my experience, the facilities that thrive are those where the conveyor is seen as a strategic asset, not just a cost This system minimizes manual handling, reduces product damage, and directly contributes to on-time order fulfillment

How Do Key Specifications Like Load Capacity and Belt Speed Directly Impact Your Bottom Line

Looking at a spec sheet can be confusing, but these numbers are directly tied to your profitability Here is a breakdown of two critical parameters for our Fortran series

-

Load Capacity This isn't just about weight It's about the integrity of your entire line An under-spec'd conveyor leads to frequent stoppages, belt damage, and costly repairs Our standard Powered Belt Conveyor Series is engineered to handle the specified load with a significant safety margin, ensuring continuous operation

-

Belt Speed Speed must be matched to your process workflow Too fast, and you risk product spillage or worker safety issues Too slow, and you create a bottleneck Our systems offer variable speed control, allowing you to fine-tune the pace to match upstream and downstream activities perfectly

| Specification | Why It Matters to Your Operation | Common Pain Point It Solves |

|---|---|---|

| Frame Material (e.g., Powder-Coated Steel) | Defines longevity and resistance to wear, corrosion, and environmental factors in harsh plants. | Frequent replacement of rusted or weakened frames, leading to unplanned downtime. |

| Motor Power (e.g., 0.5 HP - 2.0 HP) | Determines the system's ability to start under full load and maintain speed on inclines. | Burned-out motors from overexertion, causing entire production lines to halt. |

| Belt Type (e.g., PVC, Rubber, Urethane) | Directly influences grip, hygiene, noise levels, and suitability for specific products (e.g., food, packages). | Product slippage, contamination risks, or excessive noise requiring hearing protection. |

Why Is the Durability of the Frame and Belt a Make-or-Break Factor for Your Business

I have visited countless sites where the biggest pain point was not the motor, but the frame or belt failing prematurely A weak frame flexes under load, causing misalignment and excessive wear on components A subpar belt can stretch, tear, or shed material, contaminating your product and environment This is where the engineering philosophy behind the Fortran Powered Belt Conveyor Series makes a tangible difference We over-engineer these core components not to increase the price, but to drastically decrease your total cost of ownership

What Advanced Features Should You Look for Beyond the Basic Specifications

Beyond the core specs, modern material handling demands smarter systems When evaluating a Powered Belt Conveyor Series, you must consider features that future-proof your investment

-

Integrated Tracking Sensors These automatically correct belt misalignment before it causes damage, a common source of unplanned maintenance

-

Easy-Clean Designs Look for sealed components and quick-release mechanisms For industries like food or pharmaceuticals, this isn't a luxury it's a necessity for compliance

-

Modularity Can the system be easily reconfigured, extended, or integrated with other equipment like sorters or scanners Our Fortran designs prioritize this flexibility, allowing your operation to adapt and grow without a complete overhaul

How Can the Right Powered Belt Conveyor Series Future-Proof Your Entire Operation

The ultimate role of a best-in-class Powered Belt Conveyor Series is to be a reliable partner for years to come It's about building a foundation that supports growth, adapts to change, and resists obsolescence The goal is to install a system and then almost forget it's there, knowing it will perform day in and day out This reliability is the core of what we build into every Fortran system We don't just sell equipment we provide a long-term solution for seamless material movement

The right system is more than a purchase it's an investment in your operation's stability and growth If you are looking for a partner to help specify the perfect solution for your unique challenges, we are here to help Contact us today with your requirements and let our engineering team provide a tailored consultation