- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What Are the Maintenance Requirements for an Industrial Powered Belt Conveyor Series

2025-12-17

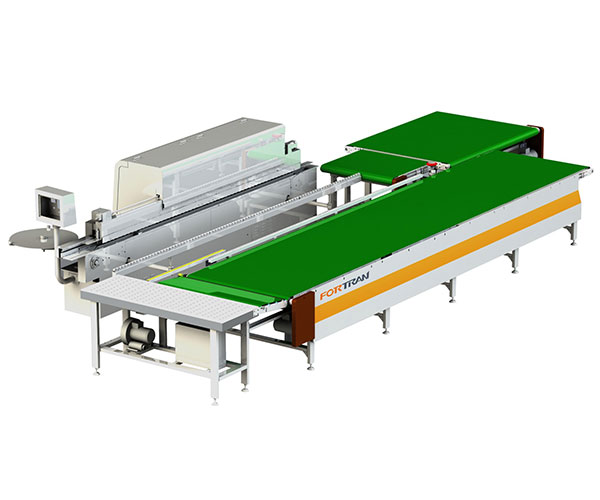

If you’re managing a busy production line, you know that unexpected conveyor downtime can bring everything to a halt. That’s why understanding the maintenance requirements for an industrial Powered Belt Conveyor Series is critical for reliability and cost savings. At Fortran, we’ve designed our series with serviceability in mind, but even the most robust systems need proper care. Let me walk you through what it takes to keep your line running smoothly and why our Fortran series stands up to the challenge.

What Daily and Weekly Checks Should You Perform

A consistent visual and operational check is your first defense against major repairs. We recommend a simple first-person walk-through at the start of each shift. Listen for unusual noises and look for material spillage along the belt path. For our Powered Belt Conveyor Series, pay special attention to:

-

Belt tracking and tension.

-

The condition of the belt surface for cuts or wear.

-

The operation of emergency stop switches and safety guards.

A quick weekly check should include verifying motor amperage and inspecting drive components. This routine for any Powered Belt Conveyor Series prevents small issues from becoming costly failures.

Which Critical Components Need Scheduled Service

Beyond daily observations, scheduled maintenance is non-negotiable. The longevity of your Powered Belt Conveyor Series depends on it. Key components and their service intervals are highlighted below:

| Component | Maintenance Task | Recommended Interval |

|---|---|---|

| Drive Motor & Gearbox | Check oil levels, lubricate per specs, inspect seals. | Quarterly |

| Bearings & Rollers | Listen for noise, check for smooth rotation, re-lubricate. | Bi-Annually |

| Conveyor Belt | Inspect for damage, measure tension, clean thoroughly. | Monthly |

| Electrical Systems | Tighten connections, check sensor alignment, test controls. | Annually |

Following this schedule ensures each part of the Fortran Powered Belt Conveyor Series operates at peak efficiency. Our design allows for easy access to these points, minimizing service time.

How Does Proper Lubrication Extend Conveyor Life

Incorrect lubrication is a leading cause of premature bearing and gear failure. The requirements differ across components. Gearmotors in our series often use synthetic oil, while roller bearings might require a specific grease. We provide detailed lubrication charts with every Fortran system because using the wrong type or over-lubricating can be just as damaging as neglect. Sticking to the prescribed lubricants and intervals for your Powered Belt Conveyor Series is one of the simplest ways to double its service life.

Can the Right Design Reduce Your Maintenance Burden

Absolutely. At Fortran, we build our conveyors to reduce your total cost of ownership. Features like sealed-for-life bearings in non-drive rollers, easily accessible belt tensioners, and modular bolt-together frames are engineered into our Powered Belt Conveyor Series. These design choices mean less frequent service and faster repairs when needed, directly addressing the pain point of prolonged downtime.

What Are the Signs You Need Professional Service or Parts

Even with perfect care, components wear out. Recognizing the signs early saves money. Persistent belt misalignment despite adjustment, increasing motor heat or noise, and visible wear on pulley lagging are clear indicators. When you see these, it’s time for professional inspection or genuine replacement parts. Using OEM-specified parts, especially for a precision Powered Belt Conveyor Series, guarantees fit and performance, protecting your investment.

A well-maintained conveyor system is the backbone of efficient production. By following these guidelines, you can maximize uptime and productivity. For a Powered Belt Conveyor Series engineered to make maintenance straightforward and keep your line moving, look to Fortran. We design for durability because we understand your operational pressures.

Ready to specify a conveyor that simplifies maintenance and boosts your bottom line? Contact us today for a detailed quote or to speak with our engineering team about your application needs.