- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Intelligent vs Traditional Packaging Line Series What Are the Key Differences

2025-12-03

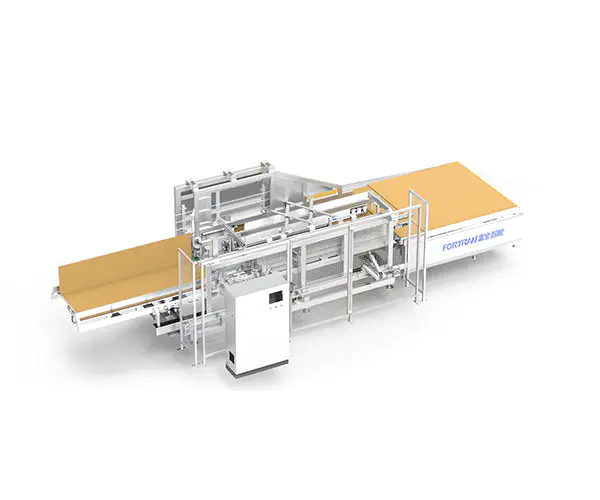

If you’re managing a production facility today, you’ve likely asked yourself this very question. The pressure to increase efficiency, reduce waste, and stay competitive is immense. At the heart of this operational evolution is a critical choice: sticking with a traditional packaging line or upgrading to an Intelligent Packaging Line Series. As a leader in innovative automation, Fortran has been at the forefront of this shift, helping businesses like yours navigate these complex decisions.

What Truly Defines an Intelligent Packaging Line Series?

Simply put, an Intelligent Packaging Line Series is a fully integrated, data-driven ecosystem. It moves beyond mere mechanization to incorporate smart sensors, real-time analytics, and self-correcting protocols. Unlike traditional setups that require constant manual oversight, an intelligent system predicts and adapts. For instance, our Fortran SmartSeries doesn’t just package products; it collects data on every cycle, monitors material integrity, and preemptively flags maintenance needs before they cause downtime.

How Do Core Parameters Compare Between Intelligent and Traditional Lines?

The differences become stark when we examine the technical specifications. Let’s break down the key parameters.

Performance Metrics:

-

Changeover Time: Traditional lines often require hours for product changeovers. An Intelligent Packaging Line Series can achieve this in minutes through automated, recipe-driven settings.

-

Overall Equipment Effectiveness (OEE): Traditional lines typically operate at 60-75% OEE. Our intelligent systems consistently deliver OEE above 90% by minimizing micro-stops and defects.

-

Energy Consumption: Intelligent lines feature smart power management, reducing energy use by up to 30% compared to conventional continuous-run systems.

Technical Specifications at a Glance:

| Parameter | Traditional Packaging Line | Fortran Intelligent Packaging Line Series |

|---|---|---|

| Control System | Programmable Logic Controller (PLC) | Integrated IoT Platform with AI Analytics |

| Data Output | Basic Production Counts | Real-time KPIs, Predictive Insights, Quality Trends |

| Downtime Response | Reactive (Manual Diagnosis) | Proactive (Automated Alerts & Root-Cause Analysis) |

| Scalability | Limited, Requires Major Hardware Add-ons | Modular, Software-Upgradable Architecture |

Why Should You Care About Connectivity and Data?

This is where the Intelligent Packaging Line Series creates unparalleled value. Traditional lines operate in a vacuum, offering little visibility into performance trends. I’ve spoken with countless plant managers who are frustrated by unexpected breakdowns and inconsistent output quality. The intelligent series from Fortran solves this by turning your packaging floor into a source of strategic intelligence. You can track performance from your office or phone, receiving actionable data that empowers your team to make better decisions faster.

Can an Intelligent System Truly Address Your Specific Pain Points?

Absolutely. The core mission of our Intelligent Packaging Line Series is to solve real-world problems. Are you struggling with:

-

Excessive material waste due to calibration drift?

-

Lengthy compliance reporting and traceability challenges?

-

High labor costs for inspection and manual adjustments?

Our systems are engineered to tackle these issues head-on. With precise, closed-loop controls, material waste plummets. Every package is digitally tracked, making batch traceability instantaneous. Automated vision inspection and adjustment free your skilled workers for more valuable tasks. This isn’t just new machinery; it’s a fundamental upgrade to your operational intelligence, a principle Fortran builds into every solution.

Is the Future of Packaging Intelligent?

The trajectory is clear. Market demands for agility, sustainability, and traceability are making traditional lines a limiting factor. Investing in an Intelligent Packaging Line Series is no longer a luxury for the future; it’s a necessity for present-day competitiveness and resilience. It represents a shift from a cost center to a strategic, data-generating asset for your business.

We at Fortran are committed to partnering with you on this journey. Our experts are ready to discuss how our intelligent series can be tailored to your unique production goals. If you’re ready to explore what a truly smart packaging operation can achieve, we encourage you to take the next step.

Contact us today for a detailed consultation. Let’s transform your packaging line into your most reliable and insightful partner.