- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

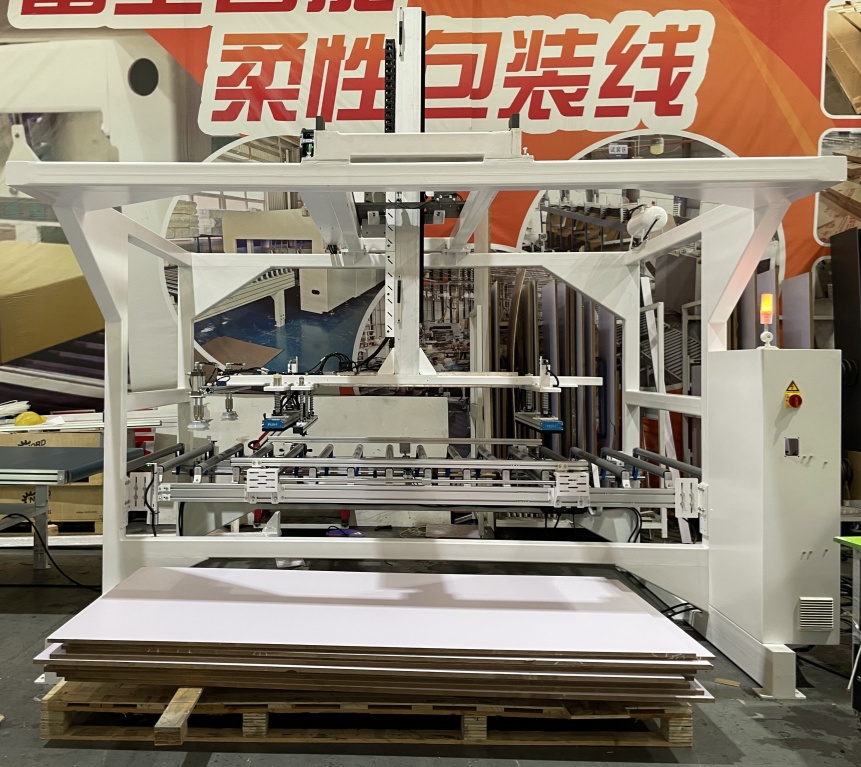

Anti-Adhesion Frame-Type Automatic Loading and Unloading Machine for Plates

2025-09-03

When furniture workpieces are loaded in entire pallets, due to the air permeability of the material, the degree of fit between workpieces,

and the adhesion of glue at the edges, the manipulator may cause mutual adhesion when grabbing workpieces:

the target is to grab one layer of workpieces, but in reality, it may grab 3-4 layers at most.

This will cause a series of negative impacts and greatly reduce the reliability of the equipment operation.

The equipment has high requirements for the plates to be loaded: the longer the plates are placed, the tighter the fit between the plates,

and the easier it is to adhere; the cleanliness of the plates and residual glue at the edges may aggravate the mutual adhesion between the plates.

The operational reliability of the equipment is poor.

Problems caused by mutual adhesion between plates require shutdown and manual intervention, and this situation occurs frequently.

There is a high safety risk: frequent abnormalities require personnel to enter and exit the manipulator's working area, which poses a great safety risk.

The suction cup grabbing cycle is not fixed: the height of the table for releasing plates is fixed, but when grabbing,

the plates are grabbed layer by layer from each pallet, and the height decreases gradually, which is constantly changing.

Therefore, it is necessary to research and develop a new type of linked feeding automation equipment to accurately feed the plates to be drilled in response to the above problems.

Workflow of Anti-Adhesion Frame-Type Automatic Loading and Unloading Machine in Wood-Based Panel Production Line

1.Loading Preparation: Workers place entire pallets of to-be-processed wood-based panels on the equipment's feeding rack. The rack's lifting platform automatically adjusts to the initial grabbing height.

2.Positioning and Grabbing: The gantry manipulator drives the grabbing mechanism to move directly above the panels. An industrial camera locates the panels' position;

the suction cups descend to contact the panel surface, and the anti-adhesion module is activated simultaneously.

3.Anti-Adhesion Detection: A tension sensor detects the load. After confirming that only a single layer of panel is grabbed, four small disc-shaped suction cups attach to one end of the panel

and shake violently up and down for a few seconds to ensure any extra adhered panels are shaken off. Then the manipulator moves along the guide rail to the feeding port of the processing equipment.

4.Precise Unloading: Once the panel is delivered to the designated position of the processing equipment, the suction cups release the vacuum to complete the loading process. At the same time,

another set of grabbing mechanisms synchronously takes out the processed panel from the equipment and transfers it to the unloading conveyor line.

5.Cyclic Operation: The lifting platform of the feeding rack gradually rises as the grabbing proceeds to keep the grabbing surface height stable. When all panels on the pallet are processed,

the equipment issues a material change prompt.