- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

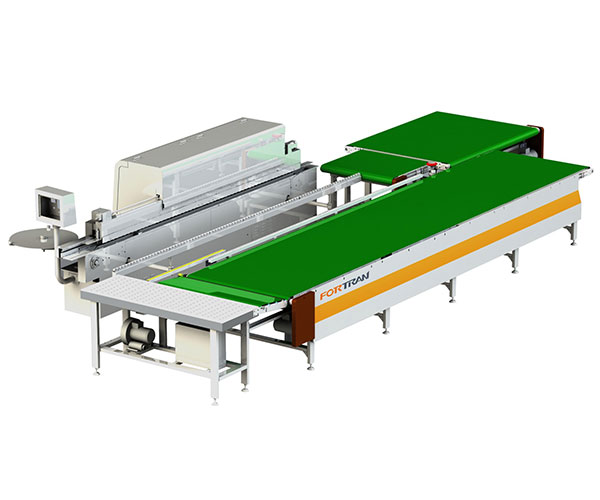

What Safety Features Should You Really Prioritize in Your Next Powered Belt Conveyor Series

I’ve spent two decades watching industries evolve online. I’ve seen the search terms shift from simple product names to complex, problem-oriented queries. One question that never fades is about safety. It’s not just about compliance; it’s about protecting your team and your bottom line. So, when you’re evaluating a new Powered Belt Conveyor Series, what separates a basic machine from a truly safe, reliable partner?

Let’s move beyond the marketing brochures and dive into the non-negotiable features that should be on your checklist.

Why is Emergency Stop Technology Your First and Most Critical Line of Defense

An E-stop isn't just a button; it's a system. You need instant, unambiguous stopping power when seconds count.

-

Pull-Cord Switches: These must run the entire length of both sides of the conveyor. Look for a design that requires a manual reset to prevent automatic restarting, which is a major safety hazard.

-

Push Button Stations: Strategically placed at both ends and at regular intervals along the frame. They should be highly visible, typically in safety red, and protected against accidental activation.

-

Zero-Voltage Release: This crucial electrical feature ensures that if power is lost and then restored, the conveyor will not automatically restart. It prevents unexpected operation that could surprise an operator.

At FORTRAN, we don’t compromise on this. Our Powered Belt Conveyor Series integrates a failsafe emergency stop system with reinforced, steel-cabled pull cords as a standard feature, not an expensive add-on.

How Can Effective Guarding Prevent Catastrophic Injuries Without Slowing Down Operations

Guarding is about creating a barrier between the worker and the hazard, but smart guarding doesn’t create a maintenance nightmare.

Common Guarding Points and Their Purpose

| Guarding Type | Hazard It Mitigates | What to Look For |

|---|---|---|

| Nip Point Guards | Where the belt meets the head or tail pulley, which can catch clothing or limbs. | Fixed, rigid metal guards that are sturdy but easily removable with tools for maintenance. |

| Side Guards | Pinch points along the sides of the frame and falling objects. | Full-length panels that are taller than the product being conveyed. |

| Underneath Guards | Access to moving rollers and underside components. | Solid sheet metal or heavy mesh that contains debris and prevents access. |

The goal is to eliminate access to moving parts without requiring a team of technicians to perform a simple belt tracking adjustment.

What Built-In Mechanisms Protect the Conveyor From Itself and Your Product

A conveyor that can protect itself from damage ultimately protects your operators from the consequences of a failure.

-

Belt Misalignment Sensors: If the belt begins to track incorrectly and rub against the frame, these sensors will shut the system down before it causes a friction fire or severe belt damage.

-

Bearing Temperature Sensors: Overheating bearings are a leading cause of fire. Monitored sensors can trigger an alarm or shutdown before a critical temperature is reached.

-

Overload Protection: Mechanical torque limiters or electronic sensors prevent the drive from burning out or damaging itself if the conveyor becomes jammed.

When we engineered the FORTRAN Powered Belt Conveyor Series, we designed these protections into the core control logic. It’s a testament to how a well-built system anticipates problems.

Is Your Conveyor Designed for Safe and Ergonomic Daily Operation

Safety isn’t just about emergency events. It’s about the daily grind. A poorly designed conveyor leads to awkward lifting, reaching, and pushing—the prime causes of musculoskeletal injuries.

Look for features that promote ergonomics:

-

Low Profile Frames: Allow for easy loading from ground level or a pallet without excessive lifting.

-

Stable, Rigid Construction: Prevents wobbling or tipping during operation or if impacted by a forklift.

-

Smooth, Continuous Welds & Rounded Edges: Eliminate sharp corners and snag points that can tear gloves or skin.

This human-centric approach to design is what we’ve championed for years. Every FORTRAN Powered Belt Conveyor Series unit is built with the operator’s physical well-being in mind, creating a safer and more productive environment.

Are You Willing to Bet Your Team's Safety on Anything Less

Choosing the right Powered Belt Conveyor Series is one of the most significant safety decisions you’ll make for your facility. It’s not a place to cut corners. It’s an investment in peace of mind, in compliance, and most importantly, in your people.

The features we’ve discussed are the blueprint for that investment. They represent a mindset where safety is engineered in, not bolted on as an afterthought.

This philosophy is at the heart of everything we do at FORTRAN. We don’t just sell equipment; we provide solutions built to protect. If you’re ready to specify a system that meets the highest standards of safety and performance, let’s have a real conversation. Contact us today to speak with one of our application engineers. Together, we can design a solution that addresses your specific operational challenges and keeps your team safe.